How to prevent low-speed nails from bending

Release time:2024-08-20 16:59:32 author:昂杰商贸 Current click through rate:171

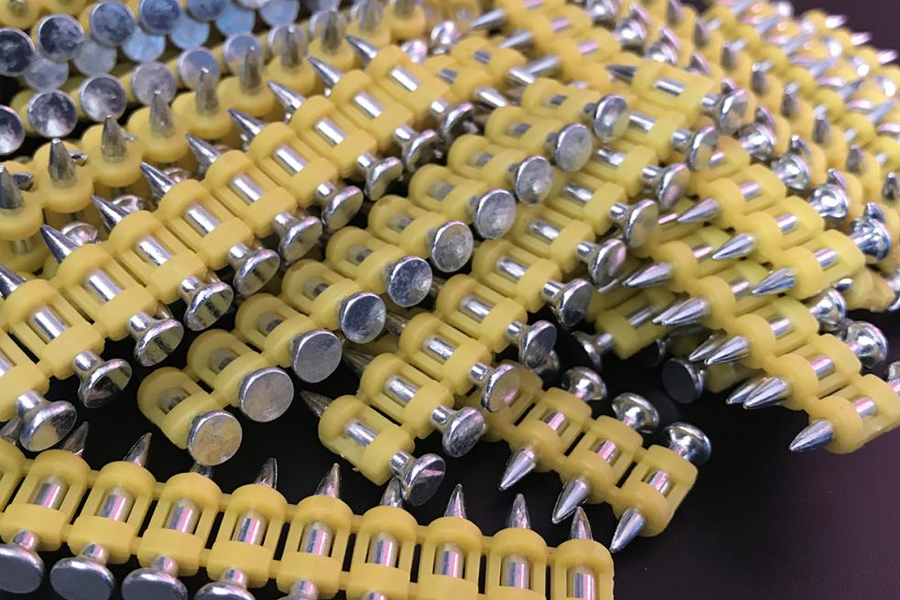

To prevent low-speed nails (understood here as fasteners similar to self tapping nails or shooting nails used in the installation of ceilings, etc.) from bending, the following aspects can be taken into account:

1. Choose the appropriate low-speed nail

Material and quality: Choose high-quality low-speed nails with excellent material quality.

. Low speed nails made of different materials have different hardness and toughness, and should be selected according to specific usage environments and requirements Specifications and dimensions: Confirm that the selected low-speed nail specifications and dimensions match the installation holes to avoid installation instability or bending caused by being too large or too small2. Accurate installation position and drilling

Accurate measurement: Before installation, the installation position of each low-speed nail should be accurately measured and determined to confirm its accuracy.

Suitable hole diameter: When drilling, a suitable drill bit should be used to confirm that the hole diameter is slightly larger than the diameter of the low-speed nail, so that the low-speed nail can be inserted and tightened smoothly. An aperture that is too large or too small may cause the installation of low-speed nails to be unstable or bent3. Correct installation method

Vertical installation: When installing low-speed nails, try to keep them perpendicular to the installation surface as much as possible to avoid tilting or skewing that may cause bending.

Appropriate force: When striking or rotating low-speed nails, appropriate force should be used to avoid excessive force that may cause the nails to bend or damage the installation surface Step by step tightening: For low-speed nails that need to be tightened step by step, they should be tightened according to the prescribed steps and torque to avoid bending caused by over tightening at once4. Use auxiliary tools

Positioning tool: You can use the positioning tool to confirm the accurate installation position of the low-speed nail.

Tightening tools: Choose suitable fastening tools, such as electric screwdrivers, pneumatic tools, etc., to improve installation efficiency and accuracy

5. Regular inspection and maintenance

Post installation inspection: After installation, each low-speed nail should be inspected to confirm that it is securely installed and free from bending.

Regular maintenance: During use, the fastening of low-speed nails should be checked regularly, and if there is any looseness, it should be tightened in a timely manner. At the same time, pay attention to observing whether there is any damage or deformation on the installation surface and promptly handle it 6. Precautions: Avoid humid environments: When installing low-speed nails in humid environments, special attention should be paid to moisture-proof measures (based on actual reports) to prevent moisture from corroding or affecting the performance of low-speed nails Follow the operating procedures: During the installation process, relevant operating procedures and standards should be followed to confirm the construction quality and safety In summary, preventing low-speed nails from bending requires starting from multiple aspects, including selecting suitable low-speed nails, accurate installation positions and drilling holes, correct installation methods, using auxiliary tools, regular inspection and maintenance, and precautions. The implementation of these measures can effectively improve the installation quality and quality of low-speed nailsOther information

-

What is the difference between a low-speed nail gun and a high-speed nail gun

There are significant differences between low-speed nail guns and high-speed nail guns in multiple aspects, mainly reflec...

-

Precautions for using low-speed nail guns

The working principle of a low-speed nail gun is mainly based on the action of gunpowder gas on the piston inside the gun...

-

How to prevent low-speed nails from bending

To prevent low-speed nails (understood here as fasteners similar to self tapping nails or shooting nails used in the inst...

-

What should be noted when installing low-speed nails

When installing a ceiling, if low-speed nails are used (assuming that "low-speed nails" refer to a type of nail suitable ...

-

Do you need to pay attention to any details when installing integrated ceiling nails

During the installation process of integrated ceiling nails, it is indeed necessary to pay attention to multiple details ...